Woodside Karratha Life Extension

Client

Woodside Energy Limited

Contract Period

Oct 2015 - Ongoing

Location

Karratha, WA, Australia

Sector

Energy

OVERVIEW

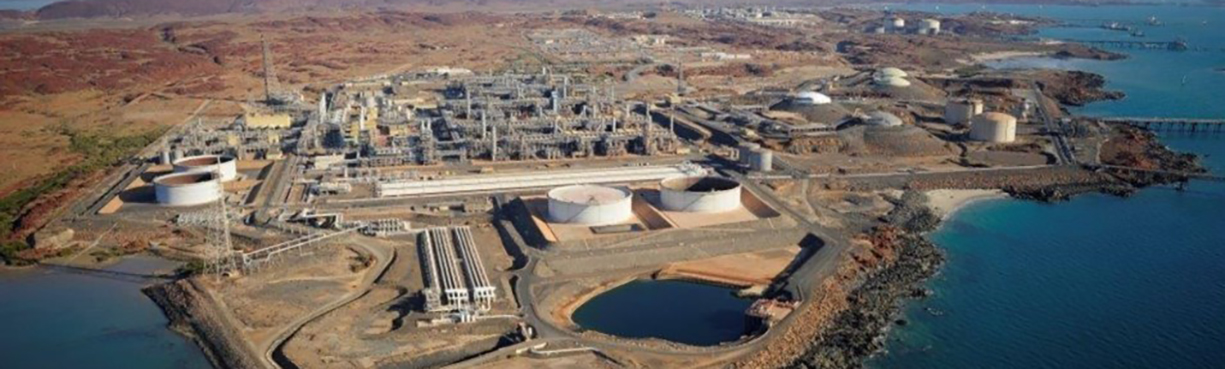

The Karratha Gas Plant (KGP) is one of the most advanced, integrated gas production systems in the world, producing LNG, domestic gas, condensate and LPG. The facility is located 1,260 kilometres north of Perth, Western Australia and covers about 200 hectares.

The KGP has an export capacity of 16.9 Mtpa, with five LNG processing trains; two domestic gas trains; six condensate stabilisation units and three LPG fractionation units.

THE SCOPE

Altrad Services, as part of a 50/50 joint venture with UGL Operations & Maintenance Pty Ltd, was originally awarded one of two site implementation contracts in 2015, for a duration of three years, as part of the Karratha Gas Plant Life Extension (KLE) Program.

The KLE Program scopes included:

- External Corrosion: a risk-based approach to identify and rectify external corrosion issues;

- Aging Facilities: address end of life issues for specific assets and equipment;

- Obsolescence: Replacement of assets, equipment and systems no longer supported by original suppliers; • Technical and reliability issues raised requiring work to be executed.

In February 2019, the joint venture was successful in negotiating a new three-year contract to become the sole provider of Onshore Brownfields Implementation Services at KGP and other selected Woodside sites across the NW Shelf as required.

Core services provided by the joint venture are:

- Access (scaffolding and rope access);

- Fire protection application;

- Blasting and painting;

- Cladding and insulation;

- Electrical and instrumentation;

- Mechanical, structural and piping.

NOTABLE BENEFITS AND ACHIEVEMENTS

- Assigned Construction Management responsibilities for all Woodside KLE subcontractors;

- Leader in the Construction in Design collaboration with the Engineering and Procurement Contractor;

- Conduct on site constructability reviews prior to deciding on the methodology for access (EWP/Rope Access/Scaffold);

- Innovative refurbishment options such as STOPAQ, HUMIDUR, dry ice blasting and auto blast & recovery systems;

- Traineeships – Seven Certificate III in surface preparation and coating application.

KEY FIGURES

- 2,645,038 Manhours to date (June 19)

- LTI Free

- Woodsides largest onshore services

provider